Surveying and product specification

Learn how PAS 13 supports safety surveys, risk reduction, and choosing the right product for the right application

How to apply PAS 13

PAS 13 is not just about robustly testing safety barriers, it is also about how these solutions are applied to your facility. Everything from pedestrian and vehicle routes through to protecting critical structures and equipment is taken into account.

Assessing risks

To start with PAS 13 looks at creating a floor plan of the facility and detailing things like, pedestrian routes and crossing points, vehicle routes and other areas where control measures may be required. The main focus is to assess where risks may occur in order to put suitable control measures in place.

Learning from the survey

On completion of the safety survey, risks and hazards will have been identified. PAS 13 looks at a range of factors to ensure all hazards are properly rectified. These factors include:

Pedestrian routes, walkways and work areas:

Industrial vehicles, heavy machinery and warehouse racking pose potentially fatal risks for pedestrians. Consider your facility layout and redirect pedestrians away from areas where vehicles move frequently.

Pedestrian crossing points:

Crossing points are among the highest risk areas in any facility. Firstly, adjusting facility layout can be an effective way to minimise risk. Redefine pedestrian walkways to avoid vehicle routes and reduce the number of crossing points.

Traffic routes:

Physically segregating people and vehicles with safety barriers can guide vehicles safely around a facility. Physical barriers define traffic routes while also offering impact protection should a collision occur.

Critical structures and equipment:

Preventing impacts with critical structures and equipment is vital. Columns, doorframes, racking, equipment and overhead assets are vulnerable to vehicle collisions, recurring impacts to these critical structures can have catastrophic consequences.

How can PAS 13 help you to select the right safety barrier?

The vehicle types operating in a warehouse facility can vary greatly. A safety barrier that is fit-for-purpose can be the difference between life and death. Therefore, matching the strength of safety barriers to the vehicles in operation is essential. PAS 13 gives specific guidance in the factors that should be considered:

Impact forces:

A barrier’s impact resilience must match the impact forces at play in the environment it will be used.

Impact resilience:

In order to provide accurate impact ratings, barrier suppliers should have tested impact resilience using repeated dynamic testing methods as outlined in PAS 13. If the rating of a barrier is lower than the potential vehicle impact force, it is not fit-for-purpose.

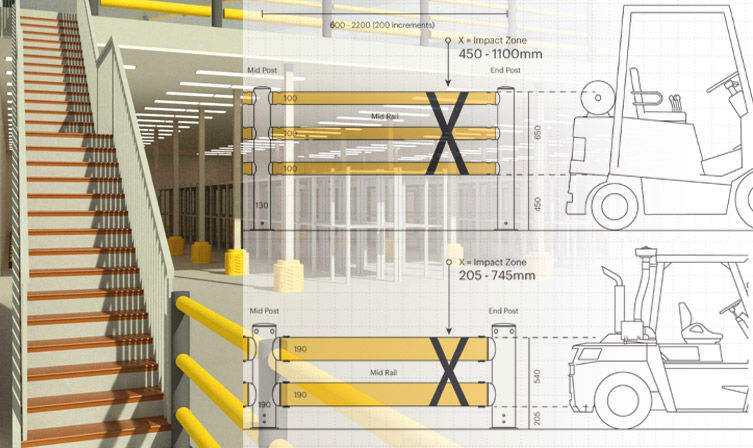

Impact zone:

The impact zone is just as important as the impact rating, for ensuring the barrier is fit-for-purpose. Carrying load, vehicle height, ground clearance, and the diameter of vehicle wheels all affect the type of barrier which is best suited.

Eye-line is another key factor that has a bearing on the most appropriate barrier impact zone. Visibility is the first line of defence. Low-level barriers and bollards might be visible to pedestrians and those handling trucks and trolleys, but they will not be visible to lorry and forklift truck drivers.

Many safety barriers are bright yellow; a universal signal hazard signal. To ensure long-term visibility, barriers should be self-coloured or undergo regular painting maintenance, this means, should an impact occur, the colour will not scrap off or fade over time.

Explore how the correct selection and use of safety barriers reduce risk.