Bollards provide an excellent level of protection at busy factories, warehouses, and other industrial facilities, but what do you need to know before investing in new safety systems? Our guide can help.

You can read the full article or jump ahead to a relevant section:

- Understanding bollards: The basics

- Industrial safety bollards & protection: What can they defend against?

- Industrial safety bollards and safety standards: What are the regulations?

1. Understanding industrial safety bollards | The basics

It’s helpful to understand some of the basics if you have never implemented new safety measures and protections on site. This section covers some FAQs about industrial bollards.

What is an industrial safety bollard?

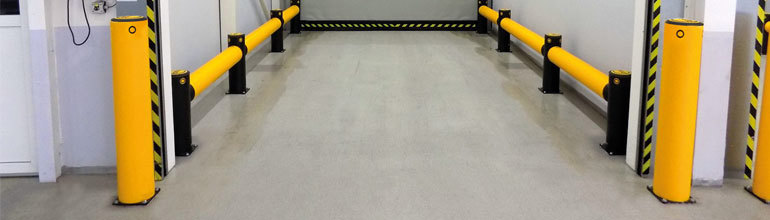

A bollard is a solid vertical post that provides robust protection from unwanted impacts, such as vehicle collisions and large forces that have the potential to cause damage.

An industrial bollard is specifically used in industrial settings, such as:

- Factories

- Warehouses

- Distribution centers

- Storage facilities

- Airports

- Parking lots and parking garages

What are the components of an industrial bollard?

The main components of an industrial bollard are the base and the post. The base is where the bollard is secured to the floor and the post is the upright that absorbs the force of impact.

Some bollards do not have a separate base but instead are a single post that is secured directly to the floor. In addition, some bollards have a core that helps to strengthen the bollard’s structure.

Where are industrial bollards used?

Industrial bollards are used throughout busy facilities where there is an increased risk of accidents involving site vehicles such as forklift trucks. They are often used to protect:

- Machinery

- Infrastructure (buildings, corners, structural columns, etc.)

- Assets (stock, goods, etc.)

They can also be used in other areas where there is a high volume of vehicles in operation, such as:

What are industrial bollards made of?

Industrial safety bollards are usually made from one of three types of material. They are:

- Concrete

- Steel

- Polymer / plastic

What is the difference between concrete, steel and polymer bollards?

Concrete, steel and polymer bollards largely perform the same function – providing robust protection from site vehicles, however each material has its own properties that can make the level of protection vary substantially.

Concrete bollards

Concrete bollards are primarily used outdoors. They are secured to the ground with cement and sometimes have a steel post at their core to strengthen them. While concrete bollards can be very effective at preventing vehicle collisions, they are usually a single-use product as one impact could render them damaged or substantially weakened.

Steel bollards

Steel bollards are traditionally the most common type of protection in industrial settings, although in recent years there has been a move towards polymer bollards. They often feature a post (sometimes with a concrete core) and a base that is bolted to the floor. While steel bollards do provide a good degree of protection, like concrete bollards, they can often be substantially weakened, damaged, or even pulled from their footings in the event of a collision, which would mean they need replacing.

Polymer bollards

Bollards that are made from polymer differ from traditional steel and concrete because they’re designed to be used again and again. Polymer is a term that is used interchangeably with 'plastic'. All plastics are polymers but when people refer to polymer bollards, they mean flexible plastic bollards that bends on impact and reforms to their original shape without incurring any substantial damage. Therefore, polymer is increasingly becoming the preferred bollard material. It is low-maintenance and highly visible making it ideal protection in busy industrial settings.

Learn more: Comparing concrete, steel and polymer bollards

Industrial safety bollards provide a protection from various impacts throughout busy facilities. At A-SAFE, our world-leading polymer bollards provides robust long-lasting protection with minimal maintenance. Speak to a member of our team to find out more.

2. Industrial safety bollards & protection | What can they defend against?

Now you know a little more about the basics of industrial bollards, it’s helpful to understand what they can protect against and how effective they can be.

Types of industrial bollards

There are two main types of industrial bollard, and they are:

- Standard bollards

- Heavy-duty bollards

As the names suggest, standard bollards are designed to handle standard impacts. Whereas heavy-duty bollards are especially useful for protecting in areas where more substantial collisions or forces are likely to pose a threat.

Both types perform the same function and operate in the same ways, but heavy-duty bollards are more robust and designed to handle larger impacts. For example, heavy-duty bollards may be used in service yards where vehicles are more likely to be large articulated lorries, rather than smaller materials handling vehicles.

What can industrial bollards protect against?

Traditionally, bollards are designed to protect against vehicle impacts. Whether this is in a parking garage, near busy roads and streets or in and industrial setting, their main purpose is to act as a barrier between vehicles and whatever it is that needs protecting.

In industrial settings, bollards can protect against a variety of vehicles and materials handling equipment, including:

- Forklift trucks

- Side-loaders

- Pallet trucks

- Cars and vans

- Semi-trailer trucks

What do industrial bollards defend?

As mentioned above, industrial barriers are designed to protect vulnerable or valuable assets on site such as:

- Machinery

- Building infrastructure

- Stock and goods

They are primarily used to protect static objects, like machinery, although they can also be used to segregate one part of a busy facility from another, such as a busy vehicle route from pedestrian workspaces. However, if this is the sort of thing you need, it may be that safety barriers are a more suitable solution.

Do I need bollards or safety barriers?

When identifying the right type of protection for your site, it’s good to consider your use for it first. Safety systems are the most effective way to keep people safe on site, however there are different systems better suited to specific needs.

For example, bollards are ideal for providing protection at:

- Sharp corners

- Door frames

- Areas where vehicles turn round

- Specific vulnerable areas of machinery or infrastructure

Whereas, safety barriers are better suited to providing protection that:

- Segregates pedestrians from vehicles

- Manages busy site traffic

- Covers a long stretch or distance

- Cordons off vulnerable structures, i.e. columns and posts

Where this differs is in instances where protection is needed to defend against site vehicles, but it cannot impede access for pedestrians. A good example would be fire safety equipment; you may want to protect your safety equipment from unwanted collisions, but pedestrians would still need to gain access quickly in the event of a fire. In this case, you could use safety barriers with a gate configuration, but a bollard would be better suited for allowing immediate access.

With this in mind, it is best to assess your site properly and identify which systems are right for your needs.

How do you know how strong a bollard is?

Almost all bollard manufacturers provide impact ratings with their products. An impact rating is a figure assigned to a product which denotes the amount of force they can withstand, usually at specific angles.

An impact rating is often given in Joules and this figure is reached by multiplying the velocity of a vehicle by its weight, while factoring in the angle of impact. This will tell you what size force a bollard can withstand, but it is best to interrogate these figures properly as some manufacturers can make misleading claims.

What can cause a bollard to be less effective?

A bollard can be rendered less effective or even destroyed if it is subjected to a force larger than the one it is designed to handle. When this happens, it is usually a result of being impacted by a vehicle that has substantially altered its speed or weight.

For example, it may have been impacted by a vehicle that is moving faster than the designated speed on site or one that is carrying a load larger than specified by the vehicle manufacturer.

Safety systems can only operate to their full potential when the wider facility safety measures are adhered to – if vehicle drivers operate responsibility and within the specified guidelines, there is no reason a bollard should fail when impacted.

Bollards provide effective protection in busy industrial sites and once you know what a bollard can handle, it’s easier to identify the right kind of protection for your needs. At A-SAFE, we’re committed to advancing facility safety and our team are always on hand to provide friendly support and advice – they can even perform a free site survey. Book a consultation now.

3. Industrial safety bollards and safety standards | What are the regulations?

Understanding the safety standards and regulations around various types of facility protection is useful as it can help you to understand what level of protection is needed. Not only that, but it’s useful to know if there are supporting safety measures that can be implemented to reduce risk.

Are there safety standards for bollards?

Currently, there are no set safety standards around the use of bollards at industrial facilities, however there are a range of guidelines and codes of practice that refer to the use of bollards. These include:

- Traffic Advisory Leaflet 02/13

- PAS 13

- PAS 68

- PAS 170-1

While not all of these are directly related to the use of bollards in industrial facilities, it is worth looking at them if you require bollards for additional protection issues.

What is Traffic Advisory Leaflet 02/13?

Created by the UK’s Department for Transport, the Traffic Advisory Leaflet 02/13 covers the topic of ‘Bollards and Pedestrian Movement’ in outdoor areas occupied by the public. It is primary focused on the use of Vehicle Security Barriers (VSBs) as used to prevent vehicle-borne terrorist threats and how that impacts on the way pedestrians navigate those areas that use bollard systems.

It is based on a range of findings gathered from different studies conducted at a range of busy sites. The main thrust of the leaflet is focused on how bollards impact:

- The rate at which pedestrians can pass through an area

- The amount of comfortable space available for pedestrians to move freely

- The convenience with which pedestrians can follow their desired routes

- Conflicts that occur in the area, i.e. pedestrians colliding with each other, sudden changes of direction, etc.

Industrial Safety Bollards and Publicly Available Specifications

Publicly Available Specifications or (PAS) refer to documents created by the British Standards Institution (BSI). These specifications are codes of practice which refer to the best way to apply a product, service, or process. It is a form of standardization though it is not legally enforced.

There are a range of PAS which refer to the uses of bollards.

What is PAS 13?

PAS 13 is the code of practice for safety barrier application and testing. It was created to standardize the use of safety barriers within industrial settings, specifically for traffic management. In addition, it provides guidelines on the most affective way to test safety barriers to provide the most accurate impact ratings.

While the focus of PAS 13 is safety barriers, it is especially relevant to the use of bollards and how they can be included within barrier systems to provide a more robust and rounded level of protection. It is certainly worth reviewing PAS 13 to understand how it can help when planning the layout of a facility and its safety systems.

What is PAS 68?

PAS 68 was designed to standardize the testing of bollards and barriers as used in preventing hostile vehicle mitigation (HVM) – in other words, where bollards are used in the prevention of vehicle-related security breaches and terror attacks.

This PAS is useful in situations where you need bollards that can prevent more substantial and deliberate impacts from vehicles, rather than the types of accidents that occur at industrial facilities.

What is PAS 170-1?

PAS 170-1 provides guidelines around the most effective ways of testing the performance of single bollards when hit by vehicles driving at low speeds.

Created for manufacturers of bollards and other distributors, PAS 170-1 is still useful to understand how bollards are affected when impacted in public parking lots, such such as supermarket parking lots.

Understanding the various safety standards and regulations around the use of bollards can be a good way to identify the level of protection you need. At A-SAFE, our polymer bollards are compliant with PAS 13 and our impact ratings provide an accurate reflection of the forces they can withstand. Contact us to find out more about PAS 13.

Industrial safety bollards | A summary

Bollards provide an essential service at busy industrial sites – not only can they prevent unwanted accidents, but they can help to make workers more aware of the safety measures in place. As you start to understand the risks present on site, you will begin to identify the right solutions. Hopefully this guide has helped to bring you up to speed on bollard protection.

At A-SAFE, we are always on-hand to offer advice, support, and guidance when it comes to improving safety at industrial workplaces. Our flexible polymer bollards are world-leading and a long-lasting and low-maintenance alternative to traditional steel and concrete bollards. To speak to a member of our team, email us at [email protected], call us on (443) 776-3472 or use the contact form below.